- Submit a Protocol

- Receive Our Alerts

- Log in

- /

- Sign up

- My Bio Page

- Edit My Profile

- Change Password

- Log Out

- EN

- EN - English

- CN - 中文

- Protocols

- Articles and Issues

- For Authors

- About

- Become a Reviewer

- EN - English

- CN - 中文

- Home

- Protocols

- Articles and Issues

- For Authors

- About

- Become a Reviewer

Thermostability Measurement of an α-Glucosidase Using a Classical Activity-based Assay and a Novel Thermofluor Method

Published: Vol 7, Iss 12, Jun 20, 2017 DOI: 10.21769/BioProtoc.2349 Views: 10592

Reviewed by: Yanjie LiAyelign M. AdalAnonymous reviewer(s)

Protocol Collections

Comprehensive collections of detailed, peer-reviewed protocols focusing on specific topics

Related protocols

An Assay to Determine NAD(P)H: Quinone Oxidoreductase Activity in Cell Extracts from Candida glabrata

Anamika Battu [...] Rupinder Kaur

Nov 5, 2021 3062 Views

Measuring in vitro ATPase Activity with High Sensitivity Using Radiolabeled ATP

Sarina Veit and Thomas Günther Pomorski

May 20, 2023 2283 Views

Use of the Fluorescent Dye Thioflavin T to Track Amyloid Structures in the Pathogenic Yeast Candida albicans

Thierry Mourer [...] Sophie Bachellier-Bassi

Feb 5, 2024 2343 Views

Abstract

α-glucosidases (including maltases and isomaltases) are enzymes which release glucose from a set of α-glucosidic substrates. Their catalytic activity, substrate specificity and thermostability can be assayed using this trait. Thermostability of proteins can also be determined using a high-throughput differential scanning fluorometry method, also named Thermofluor. We have shown that Thermofluor can also be applied to predict binding of substrates and inhibitors to a yeast α-glucosidase. The methods described here in detail were used in Viigand et al., 2016.

Keywords: MaltaseBackground

Maltases (EC 3.2.1.20) and isomaltases (EC 3.2.1.10) are α-glucosidases belonging to family 13 of glycoside hydrolases according to the CAZy classification (Lombard et al., 2014). Maltase MAL1 of a methylotrophic yeast Ogataea polymorpha is nonselective–it hydrolyses maltose- and isomaltose-like α-glucosidic sugars producing D-glucose as one of the reaction products. Thus, activity of maltase on its substrates can be determined according to glucose release. The Glucose liquicolor-aided method described in this work allows rapid and convenient assay of the activity, substrate specificity and thermostability of the maltase. Importantly, this activity-based method can be adapted to other enzymes that produce glucose as a reaction product. A high-throughput Thermofluor method is mostly used in protein crystallography to measure (thermal) stability of the protein (Boivin et al., 2013; Ericsson et al., 2006). We used Thermofluor 1) to evaluate thermostability of the maltase protein and 2) to study its substrate specificity (Viigand et al., 2016). Substrate specificity assay of glycoside hydrolases and other sugar-acting enzymes using Thermofluor is cost-efficient–it requires very low amounts of the protein as well as ligand sugars that can be very expensive. Regarding substrates of α-glucosidases, one gram of isomaltose from Sigma-Aldrich costs almost 1,000 euros, 10 milligrams of nigerose 143 euros and 1 mg of kojibiose almost 200 euros.

Materials and Reagents

- For both methods

- 1.5 ml microtubes (Corning, Axygen®, catalog number: MCT-150-C )

- 0.2 μm cellulose acetate membrane filter (Sartorius, catalog number: 11107-47-N )

- Sucrose (Sigma-Aldrich, catalog number: 16104 )

- MilliQ quality water (MQ)

- Crushed ice

- In-house laboratory purified C-terminally His-tagged maltase MAL1 (from Ogataea polymorpha) and its inactive mutant protein (Asp199Ala) overexpressed in Escherichia coli (prepared as in Viigand et al., 2016)

- 1.5 ml microtubes (Corning, Axygen®, catalog number: MCT-150-C )

- For classical activity assay

- Special PS (polystyrene) micro photometer cuvette, 2 ml (LP ITALIANA, catalog number: 112117 )

- Glucose liquicolor kit (GOD-PAP Method, Enzymatic Colorimetric Test for Glucose) (Human, catalog number: 10260 )

- Potassium phosphate monobasic (KH2PO4) (Sigma-Aldrich, catalog number: 795488 )

- Potassium phosphate dibasic (K2HPO4) (Sigma-Aldrich, catalog number: RES20765 )

- Ethylenediaminetetraacetic acid (EDTA) (Sigma-Aldrich, catalog number: E9884 )

- Tris base (Roche Molecular Systems, catalog number: 10708976001 )

- Hydrochloric acid 37% (HCl) (AppliChem, catalog number: A0659 )

- 1 M Tris-HCl buffer (pH 8.3) (see Recipes)

- Maltase buffer (see Recipes)

- Special PS (polystyrene) micro photometer cuvette, 2 ml (LP ITALIANA, catalog number: 112117 )

- For Thermofluor method

- LightCycler® 480 Multiwell Plate 96 (white) with sealing foils (Roche Molecular Systems, catalog number: 04729692001 )

- 5,000x SYPRO Orange Protein Gel Stain (Sigma-Aldrich, catalog number: S5692 )

- HEPES buffer (Sigma-Aldrich, catalog number: H3375 )

- Sodium hydroxide (NaOH) (AppliChem, catalog number: 131687.1211 )

- Sodium chloride (NaCl) (Sigma-Aldrich, catalog number: 31434-M )

- 0.5 M HEPES buffer (pH 7.0) (see Recipes)

- 4x Thermofluor buffer (see Recipes)

- LightCycler® 480 Multiwell Plate 96 (white) with sealing foils (Roche Molecular Systems, catalog number: 04729692001 )

Equipment

- Pharmaceutical balance PS2100/C/2 (RADWAG Balances and Scales, model: PS 2100/C/2 )

- JENWAY pH meter model 3510 (Cole-Parmer Instrument, model: Jenway 3510 )

- Pipettes (FisherbrandTM Elite Pipette Kit) (Fisher Scientific, catalog number: 14-388-100 )

- Refrigerator-freezer (Electrolux, model: EN2900AOW )

- Ultrospec 3100 pro UV/Visible spectrophotometer (GE Healthcare, Amersham Biosciences, model: Ultrospec 3100 pro , catalog number: 80-2112-37)

- ThermoBlock TDB-120 (Biosan, model: TDB-120 )

- Digital timer/clock (Fisher Scientific, catalog number: S01619 )

- Plate sealer spatula for microtiter plates (Thermo Fisher Scientific, Thermo ScientificTM, catalog number: 5701 )

- LightCycler® 480 Instrument II (Roche Molecular Systems, model: LightCycler® 480 Instrument II , catalog number: 05015278001)

- Refrigerated centrifuge 4K-15 (Sigma Laborzentrifugen, model: 4K-15 , catalog number: 10742) with the swing-out rotor for 4 buckets (Sigma Laborzentrifugen, catalog number: 11150 ) and bucket, aluminium, for microtiter plates (Sigma Laborzentrifugen, catalog number: 13220 )

Note: A classical thermostability assay of the maltase is based on determination of residual catalytic activity of the enzyme after its incubation at various temperatures. Therefore, we first give the protocol for the measurement of maltase activity.

Procedure

- Maltase activity assay: The principle of the method

Maltase (MAL1) of Ogataea (Hansenula) polymorpha hydrolyses α-glycosidic linkages in numerous di- and trisaccharides (Figure 1A) typically releasing one molecule of glucose per molecule of the cleaved substrate. In case of some substrates, for example maltose and isomaltose, two glucose molecules are produced. Maltase activity is determined at a chosen temperature (we routinely use 37 °C) by monitoring the initial velocity of substrate hydrolysis according to the release of glucose. The method described here is a modification of the method of Hackel (1975) for determination of invertase activity in baker’s yeast, and was also used by us in Viigand et al., 2016. In the protocol presented here, sucrose is used as the substrate for the enzyme. The Km of sucrose hydrolysis reaction of MAL1 is ~25 mM (Viigand et al., 2016). We use two times higher concentration (50 mM) of sucrose for the maltase activity assay. The amount of glucose released from sucrose in maltase reaction is determined using a commercial Glucose liquicolor kit (Figure 1B).

A standard reaction mixture (1 ml in total) contains the maltase buffer (see Recipes), 50 mM sucrose and 3.6 μg of maltase protein. Maltase was purified using immobilized metal affinity chromatography. Our data shows that the protein’s catalytic activity is not reduced after months of storage at 4 °C.

Figure 1. Schematic overview of MAL1 substrates, their expected binding to the enzyme (A) and the maltase assay via determination of released glucose with Glucose liquicolor reagent (B). A. Monosaccharidic composition and linkage types of O. polymorpha maltase substrates and their predicted binding to subsites -1, +1 and +2 on maltase protein are indicated. Glucose residue of the non-reducing end of di- or trisaccharidic substrates is considered to bind at -1 subsite. Cleavage of the glycosidic linkage by maltase is executed between the residues bound at -1 and +1 subsites releasing the hydrolysis products into the reaction medium. The arrow on the background shows increase of the affinity of the enzyme towards the depicted substrate. The figure is based on Figure 1 of Viigand et al. (2016). B. Scheme of maltase activity measurement using Glucose liquicolor reactive. Free glucose (green circle) released from a maltase substrate (e.g., sucrose) is oxidised by the glucose oxidase to gluconic acid and hydrogen peroxide. Peroxidase uses hydrogen-peroxide to oxidize 4-aminoantipyrine in the presence of phenol to red-violet quinoneimine. The absorbance of the quinoneimine is measured at 500 nm wavelength. The colour of the product measured in Glucose liquicolor assay is also shown in Table 1 (see the cuvettes).

- Two parallel samples (two repeats) of 850 μl of maltase buffer and 50 μl (3.6 μg) of maltase protein (appropriately diluted in maltase buffer) are pre-incubated in 1.5 ml microtubes for 5 min on a thermoblock (Figure 2) adjusted to 37 °C to warm up the mixture.

Note: The maltase protein stock solution should be kept on ice during the experiment.

Figure 2. The Biosan thermoblock - Reaction is initiated by adding 100 μl of 500 mM sucrose stock solution (in maltase buffer) to the pre-heated mixture of the buffer and maltase protein, mixed and the timer is started. Incubation is conducted for required time (usually from 2 to 20 min, depending on catalytic activity of the maltase protein) and two parallel samples (50 μl) are withdrawn from each tube at each time point during the reaction. In case of the maltase preparation with a high catalytic activity, sampling should be for example at 2, 4, 6 and 8 min from the start of the reaction.

Note: Initial velocity of the reaction should be measured–meaning that the amount of released glucose should increase linearly during the reaction time. Maltase activity measurement should be repeated if the reaction slows down. In repeated experiment, we recommend using a lower amount of maltase protein. - 50 μl samples withdrawn from the reaction mixture are pipetted into 1.5 ml microtubes containing 150 μl of stopping solution of 200 mM Tris-HCl buffer with pH 8.3 and heated for 5 min at 96 °C in the thermoblock.

Note: Preparation of 1 M Tris-HCl buffer is shown in Recipes section 1. Dilution to obtain 200 mM buffer was made in MQ water. - The stopped reaction samples are cooled on ice.

- 800 μl of Glucose liquicolor reagent is added to each stopped sample and thoroughly shaken by hand.

- The microtubes with the samples are incubated at 37 °C with open lids for 5 min. The solution turns purple due to conversion of glucose into quinoneimine (Figure 1B).

- Absorbance of purple quinoneimine is measured using special PS micro photometer cuvettes with path-length of 1 cm (Table 1, column on the right) with a spectrophotometer at 500 nm wavelength against the reference (blank control).

Notes:

- For reference, 900 μl maltase buffer is mixed with 100 μl of 500 mM sucrose. 50 μl is withdrawn from this mixture and combined with 150 μl of stopping solution and 800 μl of Glucose liquicolor reagent and incubated at 37 °C with open lid for 5 min.

- The most suitable range for OD500 measurement is from 0.1 to 1.0 that ensures linearity between the OD500 measurement and glucose concentration of the solution.

- Two parallel samples (two repeats) of 850 μl of maltase buffer and 50 μl (3.6 μg) of maltase protein (appropriately diluted in maltase buffer) are pre-incubated in 1.5 ml microtubes for 5 min on a thermoblock (Figure 2) adjusted to 37 °C to warm up the mixture.

- A maltase thermostability assay

- 50 μl of maltase protein preparation is added to 850 μl of maltase buffer (final concentration of maltase protein 0.0036 mg/ml [3.6 µg/ml]). At least duplicate samples should be prepared for each temperature studied.

- The mixture (900 μl) is incubated on a thermoblock at various temperatures (in this experiment from 30 °C to 50 °C) for 30 min.

- After the thermal treatment the samples are cooled on ice.

Note: We recommend to collect all thermally inactivated samples (keeping them on ice) before proceeding with their further analysis (see the next step). - The cooled samples are warmed to 37 °C (~5 min) on a thermoblock and the reaction is started by adding the maltase substrate (100 μl of 500 mM sucrose; final concentration of sucrose in the reaction mixture 50 mM).

- Continue as described in Procedure A: Maltase activity assay, step 3.

- 50 μl of maltase protein preparation is added to 850 μl of maltase buffer (final concentration of maltase protein 0.0036 mg/ml [3.6 µg/ml]). At least duplicate samples should be prepared for each temperature studied.

Data analysis

- Maltase activity assay

Calculate maltase activity (E) according to the formula: OD500 (1 min)/(ε x [c]). OD500 (1 min) is absorbance (optical density) change of the reaction mixture per 1 min measured at 500 nm wavelength; [c] is concentration of the maltase protein (mg/ml) in the reaction mixture (see step B1) and (ε) is the extinction coefficient withdrawn from glucose calibration curve (see section Notes: Calibration curve for glucose concentration determination).

The maltase activity is expressed as the amount of maltase substrate in μmol (sucrose in current example) that is hydrolysed per min per mg of protein. The activity is expressed as μmol/(min x mg) or U/mg.

Note: The activity measured according to glucose production should be divided by two if two glucose molecules are released due to hydrolysis of the maltase substrate (for example maltose or isomaltose; Figure 1A).

An example of calculation: - Data from the experiment:

- 0.0036 mg/ml of maltase protein reacted with 50 mM sucrose.

- Samples were withdrawn at every 2 min during 6 min of the reaction, stopped and free glucose in the samples was determined by using Glucose liquicolor method (see Table 1, first column ‘OD500’).

Note: During the sampling time (6 min), reaction velocity stayed ~ constant (see Table 1, third column ‘OD500 [1 min]’). - Calculations:

- Average OD500 per 1 min was 0.731/6 = 0.122.

- 0.292 is used as extinction coefficient (ε) (see section Notes: Calibration curve for glucose concentration determination).

- Maltase activity E = 0.122/(0.292 x 0.0036) = 115.9 μmol/(min x mg) or 115.9 U/mg.

115.9 μmol of sucrose were hydrolysed by 1 mg of maltase protein during 1 min.

Table 1. Example of calculation of maltase activity

- A maltase thermostability assay

The melting temperature (Tm) of the enzyme is considered the temperature which results in 50% reduction of its catalytic activity after a 30-min incubation. The calculated Tm of the maltase protein is ~44.4 °C (Figure 3).

Figure 3. Thermostability of O. polymorpha maltase MAL1 evaluated according to residual catalytic activity. Mean values and standard deviations were calculated from at least three independent measurements.

A catalytically inactive mutant of the O. polymorpha maltase MAL1, where nucleophile Asp199 is substituted with Ala, is used in this experiment. This substitution enables to study thermostability of MAL1 in the presence of its substrates (see Figure 1A) without consecutive catalytic reaction (Viigand et al., 2016). A real-time PCR equipment is used enabling online monitoring of protein denaturation during its gradual heating in the presence of a fluorescent dye, SYPRO Orange. The dye binds to hydrophobic amino acids of the protein which become exposed at denaturation of the protein due to heating. The fluorescence intensity is plotted as a function of temperature generating a sigmoidal curve (see Figure 5). Inflection point (Tm) of this curve corresponds to the temperature at which 50% of the protein is unfolded. In this protocol, we used sucrose as a ligand sugar to evaluate its stabilizing effect on the maltase protein. In Viigand et al. (2016) we used several additional potential substrates (e.g., maltose, maltulose and palatinose) and inhibitors (e.g., glucose) of the maltase to predict which substrates and how strongly may bind the enzyme.

Procedure

- A multiwell plate 96 of the LightCycler® 480 is cooled on crushed ice or in the freezer before the experiment.

- The LightCycler® 480 should be warmed up before starting the analysis.

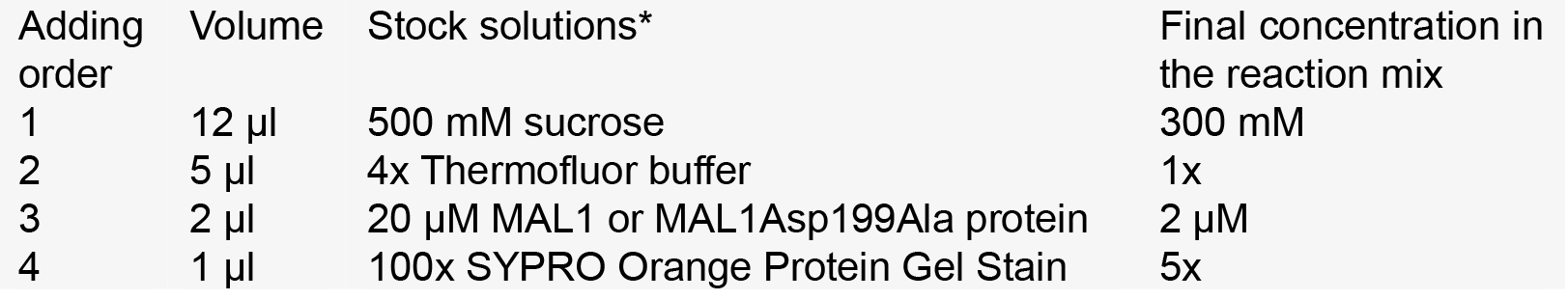

- The following ingredients are added one by one, final volume of the mixture is 20 μl per sample:

Notes: - *All stock solutions are dissolved in MQ water.

- All components should be mixed as fast as possible to minimize evaporation. The Multiwell plate should be kept on crushed ice and protected from the light. Control samples contain MQ water instead of sucrose.

- The 96-well plate is covered with a LightCycler® 480 Multiwell Plate 96 (white) sealing foils and sealed tightly with a spatula by pressing the spatula to each well.

- The sealed plate is centrifuged for 30 sec at 10 °C (a refrigerated centrifuge 4K-15) at 200 x g.

Note: The rotor of the centrifuge must be balanced with a similar plate for example with one from a previous experiment. Mild centrifugation removes the bubbles and ensures that all liquid is remaining at the bottom of the well. - The program to be used for the thermostability assay is: LightCycler® 480 SW 1.5.

- We use wavelengths of 465 nm for excitation and 580 nm for emission as in Layton and Hellinga (2010).

- Program: Melting curves; temperature is raised from 25 °C to 95 °C; 30 fluorescence measurements are taken per 1 degree of temperature increase.

- The experiment takes about 45 min.

- Data are collected by exporting the .txt file. Further analysis of the raw data is described in ‘Data analysis’.

Data analysis

Data analysis of the Thermofluor experiment

- All data are exported as a .txt file (Figure 4).

Figure 4. Data from a Thermofluor experiment saved in a .txt file (a screenshot) - Further analysis is carried out using Microsoft Excel. The fluorescence emission values (F1, F2, F3 etc.) recorded for each well during the assay are copied horizontally below the row showing temperature values (T1, T2, T3 etc.) corresponding to respective fluorescence (Figure 5, upper panel).

Figure 5. Organization of Thermofluor data for Excel-based analysis (upper panel) and an illustrative fluorescence vs. temperature graph (lower panel). Catalytically inactive maltase protein is gradually heated without ligands (no ligand) and in the presence of 300 mM sucrose. Fluorescence signal is plotted as a function of temperature to get a sigmoidal melting curve of the protein (lower panel of the figure). Fluorescence of the samples increases when the protein starts to unfold. Maximal fluorescence intensity is observed at complete unfolding of the protein. After that the SYPRO Orange signal decreases due to dye-protein dissociation as described in Boivin et al. (2013). Presence of enzyme’s substrate, sucrose, increases thermostability of the protein by 5.8 °C–the melting temperature Tm increases from 59.5 °C (no ligand added; shown in yellow) to 65.3 °C (in the presence of sucrose; shown in blue). - Though the Tm value of a protein can be roughly derived from the raw data graph as in Figure 5, further data analysis described in Niesen et al. (2007) and Boivin et al. (2013) is required for more accurate Tm determination.

- For that, we processed the raw data from Thermofluor assay, removing most of fluorescence values and keeping only those corresponding to temperature increase by ~0.5 °C.

- The first derivative was then calculated from the processed data. The first derivative (m) was expressed as:

where, Δy is the change in fluorescence intensity and Δx is the change in temperature increase corresponding to respective fluorescence change. - The temperature which corresponds to the peak of the first derivative curve represents the Tm value.

- The Thermofluor Tm data presented in Figure 5 and in Viigand et al. (2016) were obtained using the latter approach.

Tm of the catalytically inactive mutant Asp199Ala of MAL1 in the absence of sugar ligands determined by us in Thermofluor assay was 59.5 °C. Respective value of the wild-type (catalytically active) MAL1 was 51.0 (Viigand et al., 2016). Thus, the inactive mutant was more stable than the wild-type enzyme. Tm of the wild-type MAL1 determined using a classical activity-based assay was 44.4 °C (Figure 3) being lower than the Tm detected from the Thermofluor assay. As described in this paper, in a classical thermostability assay the protein is heated at selected temperatures during 30 min and after that the residual catalytic activity is measured. In the case of Thermofluor assay, the protein is heated gradually (1.5 °C per min) and subsequent denaturation is monitored online. These data show that the maltase protein tolerates short-term gradual heating better than the extended stepwise one. When the maltase mutant Asp199Ala was assayed using Thermofluor in the presence of enzyme’s substrate (see Figure 5 of this protocol and Viigand et al., 2016) or inhibitors (Viigand et al., 2016), the Tm of the protein was increased.

Notes

Calibration curve for glucose concentration determination

- 1-5.55 mM glucose solutions in maltase buffer are prepared from the glucose standard (1 mg/ml; 5.55 mM) of the Glucose liquicolor kit.

- Duplicate samples of 50 μl of glucose calibration curve solutions (1-5.55 mM) are mixed with 150 μl of 200 mM Tris-HCl buffer (pH 8.3) and 800 μl of Glucose liquicolor reactive in 1.5 ml microtubes.

- Samples are incubated at 37 °C with open lids for 5 min.

- Optical density of the purple product (quinoneimine) is measured at 500 nm wavelength with a spectrophotometer against the reference. Reference contains maltase buffer instead of the glucose solution and it is treated similarly as glucose-containing solutions of the calibration curve.

- The obtained values are plotted as in Figure 6.

Figure 6. Calibration curve for glucose concentration determination using the Glucose liquicolor kit. Quinoneimine formation was measured at 500 nm wavelength for different glucose concentrations: 0 mM, 1 mM, 2 mM, 3 mM, 4 mM, 5 mM, and 5.55 mM. - Slope of the linear trendline of Figure 6 (functions: Set Intercept and Display equation on chart) is used in maltase activity calculations as an extinction coefficient (ε) to calculate the amount of glucose released in the maltase reaction.

Recipes

- 1 M Tris-HCl buffer (pH 8.3)

- Dissolve 24.228 g of Tris base in 150 ml of MQ water

- Adjust pH to 8.3 with 37% HCl

- Complete to 200 ml with MQ water and filter through a 0.2 μm cellulose acetate membrane

- Store at room temperature

- Maltase buffer–100 mM potassium-phosphate buffer (pH 6.5) with 0.1 mM EDTA

- Prepare 1 M stock solution for potassium phosphate dibasic (K2HPO4) and potassium phosphate monobasic (KH2PO4) salts in MQ water

- Prepare 0.5 M EDTA solution in MQ water

- For 400 ml 100 mM maltase buffer (pH 6.5) mix 14 ml of 1 M K2HPO4 (alkaline component) and 26 ml of 1 M KH2PO4 (acidic component). The buffer is prepared using pre-calculated amounts of acidic and alkaline components of the same molarity to obtain the desired pH value of the buffer (Gomori, 1955)

- Add 80 μl 0.5 M EDTA

- Complete to 400 ml with MQ water

- Filter through a 0.2 μm cellulose acetate membrane filter and store at 4 °C

- 0.5 M HEPES buffer (pH 7.0)

- Dissolve 5.96 g of HEPES in 40 ml of MQ water

- Adjust pH to 7.0 with 10 N NaOH

- Add MQ water to a final volume of 50 ml

- Filter through a 0.2 μm cellulose acetate membrane filter and store at 4 °C

- 4x Thermofluor buffer

- Prepare 0.5 M HEPES stock-buffer (pH 7.0) in MQ water

- Prepare 5 M NaCl stock-solution in MQ water

- Mix 800 μl of 0.5 M HEPES buffer, 120 μl of 5 M NaCl and 80 μl of MQ water to final volume of 1 ml

- Prepare new buffer solution for each experiment

Acknowledgments

This work was financed by ERC grants GLOMR9072 (ETF9072) and GLTMR1050P (PUT1050). Brief description of the methods is presented in a paper Viigand, K., Visnapuu, T., Mardo, K., Aasamets, A. and Alamäe, T. (2016). Maltase protein of Ogataea (Hansenula) polymorpha is a counterpart to the resurrected ancestor protein ancMALS of yeast maltases and isomaltases. Yeast 33(8): 415-432. We thank Dimitri Lubenets for kind assistance in the Thermofluor assay.

References

- Boivin, S., Kozak, S. and Meijers, R. (2013). Optimization of protein purification and characterization using Thermofluor screens. Protein Expr Purif 91(2): 192-206.

- Gomori, G. (1955). Preparation of buffers for use in enzyme studies. Meth Enzymol 1: 143-146.

- Ericsson, U. B., Hallberg, B. M., Detitta, G. T., Dekker, N. and Nordlund, P. (2006). Thermofluor-based high-throughput stability optimization of proteins for structural studies. Anal Biochem 357(2): 289-298

- Hackel, R. A. (1975). Genetic control of invertase formation in Saccharomyces cerevisiae. I. Isolation and characterization of mutants affecting sucrose utilization. Mol Gen Genet 140(4): 361-370.

- Layton, C. J. and Hellinga, H. W. (2010). Thermodynamic analysis of ligand-induced changes in protein thermal unfolding applied to high-throughput determination of ligand affinities with extrinsic fluorescent dyes. Biochemistry 49(51): 10831-10841.

- Lombard, V., Golaconda Ramulu, H., Drula, E., Coutinho, P. M. and Henrissat, B. (2014). The Carbohydrate-active enzymes database (CAZy) in 2013. Nucleic Acids Res 42: D490-D495.

- Niesen, F. H., Berglund, H. and Vedadi, M. (2007). The use of differential scanning fluorimetry to detect ligand interactions that promote protein stability. Nat Protoc 2(9): 2212-2221.

- Viigand, K., Visnapuu, T., Mardo, K., Aasamets, A. and Alamae, T. (2016). Maltase protein of Ogataea (Hansenula) polymorpha is a counterpart to the resurrected ancestor protein ancMALS of yeast maltases and isomaltases. Yeast 33 (8): 415-432.

Article Information

Copyright

© 2017 The Authors; exclusive licensee Bio-protocol LLC.

How to cite

Ernits, K., Viigand, K., Visnapuu, T., Põšnograjeva, K. and Alamäe, T. (2017). Thermostability Measurement of an α-Glucosidase Using a Classical Activity-based Assay and a Novel Thermofluor Method. Bio-protocol 7(12): e2349. DOI: 10.21769/BioProtoc.2349.

Category

Biochemistry > Protein > Fluorescence

Biochemistry > Protein > Activity

Do you have any questions about this protocol?

Post your question to gather feedback from the community. We will also invite the authors of this article to respond.

Share

Bluesky

X

Copy link