- EN - English

- CN - 中文

Co-culture Wood Block Decay Test with Bacteria and Wood Rotting Fungi to Analyse Synergism/Antagonism during Wood Degradation

细菌和木材腐烂真菌共培养木块腐烂实验,分析木材降解过程中的协同/拮抗作用

(*contributed equally to this work) 发布: 2023年10月05日第13卷第19期 DOI: 10.21769/BioProtoc.4837 浏览次数: 1859

评审: Xiaofei LiangYufang LuKristin L. ShinglerAnonymous reviewer(s)

Abstract

Mixed communities of fungi and bacteria have been shown to be more efficient in degrading wood than fungi alone. Some standardised protocols for quantification of the wood decay ability of fungi have been developed (e.g., DIN V ENV 12038:2002 as the legal standard to test for the resistance of wood against wood-destroying basidiomycetes in Germany). Here, we describe a step-by-step protocol developed from the official standard DIN V ENV12038 to test combinations of bacteria and fungi for their combined wood degradation ability. Equally sized wood blocks are inoculated with wood decay fungi and bacterial strains. Axenic controls allow the analysis of varying degradation rates via comparison of the wood dry weights at the end of the experiments. This protocol provides new opportunities in exploration of inter- and intra-kingdom interactions in the wood-related environment and forms the basis for microcosm experiments.

Key features

• Quantification of wood decay ability of mixed cultures.

• Allows testing if fungi are more efficient in degrading wood when bacteria are present.

Keywords: ENV 12038 standard (ENV 12038 标准)Background

In nature, basidiomycetous fungi are associated with other microbes including prokaryotes and eukaryotes. This results in complex competitive and antagonistic interactions as well as commensal and mutualistic behaviour (Boer et al., 2005; Kobayashi and Crouch, 2009). Fungi are the most efficient wood decomposers, as their multicellular appearance and hyphal growth harbour a mobility advantage in comparison to prokaryotes. Nonetheless, bacteria are known to have direct influence on the decay process as well, by e.g., degrading complex wood components like cellulose, lignin, and hemicellulose (McGuire and Treseder, 2010) or by altering wood permeability and structure, thus improving accessibility of the wooden microfibrils (Clausen, 1996), aiding other organisms in wood decay. Synergistically acting species benefit from each other’s enzymatic abilities when they are cultivated on wood (Cortes-Tolalpa et al., 2017; Sugano et al., 2021). These results highlight the importance of inter- and intra-kingdom interactions, as they show that the combined action of different species enhances the decay ability of the whole community.

To date, several protocols and studies exist for the assessment of wood resistance against wood-destroying basidiomycetes [e.g., DIN V ENV 12038:2002 (German Institute for Standardisation, 2002), wood block test of Bravery (1978), or work of Lohwag (1965) and Hegarty et al. (1987)]. However, as these protocols evolved in large part to study timber preservation and were not designed to study the influence of other microbes, we adapted a protocol based on DIN V ENV 12038:2002 to the here described co-culture wood block decay test. This step-by-step protocol provides an easily feasible standard procedure for the assessment of wood decay properties of mixed cultures in comparison to axenic decay rates by evaluating the dry weight of wood blocks that were exposed to microbial deterioration. The purpose of this wood decay assay is to determine the influence of bacteria on the decay properties of wood rotting fungi like Serpula lacrymans [see e.g., Embacher et al. (2022), article in prep.].

Materials and reagents

Fungal and bacterial strains

Fungal strain to test [Serpula lacrymans, origin: Innsbruck, no. 1SLIBK2018 (Embacher et al., 2021)]

Bacterial strains to test [e.g., Microbacterium spp. (Embacher et al., 2021 and 2022)]

Materials

Autoclaved wood blocks (50 mm × 25 mm × 15 mm) (e.g., Picea abies; all blocks for one experiment should originate from the same batch timber)

Vessels (88 mm height, Ø 75 mm, volume 300 mL, e.g., ROTILABO®, catalog number: EP28.1) filled with 25 mL malt extract agar

Petri dishes 94 mm × 16 mm, without vents (Greiner Bio-One, catalog number: 632180)

Pre-cultured bacterial isolates to be tested

Pre-cultured fungal strain(s) to be tested (e.g., the wood rotting fungus S. lacrymans)

FisherbrandTM Easy ReaderTM conic centrifuge tubes 15 mL, PP (Fisher Scientific, catalog number: 11819650)

Sterile toothpicks

1.5 mL microcentrifuge tubes (Greiner Bio-One, catalog number: 616201)

Reagents

Casein peptone (Roth, catalog number: 8952.2)

Soy peptone (Roth, catalog number: 2365.2)

NaCl (Roth, catalog number: 0601.1)

Agar (Roth, catalog number: 5210.2)

Malt extract (Roth, catalog number: X976.2)

dH2O

D(+)-Glucose monohydrate (Roth, catalog number: 6780.1)

(NH4)2HPO4 (Roth, catalog number: P736.1)

KH2PO4 (Roth, catalog number: 3904.1)

MgSO4·7H2O (Roth, catalog number: T888.1)

CaCl2·2H2O (Roth, catalog number: T885.1)

FeCl3 (Roth, catalog number: 5192.1)

Thiamine-HCl (Roth, catalog number: T911.1)

EDTA disodium salt (Roth, catalog number: 8043.1)

ZnSO4·7H2O (Roth, catalog number: K301.2)

H3BO3 (Roth, catalog number: 5935.1)

MnCl2·4H2O (Roth, catalog number: 0276.1)

CoCl2·6H2O (Roth, catalog number: 7095.1)

CuSO4·5H2O (Roth, catalog number: 8175.6)

(NH4)6Mo7O24·4H2O (Roth, catalog number: 7311.1)

FeSO4·7H2O (Roth, catalog number: P015.1)

KOH (Roth, catalog number: 6751.1)

NaOH (9356.1)

PCR reagents:

Red Taq 2× DNA Polymerase Master Mix (VWR, Radnor, USA)

Primers 27F (5′-AGA GTT TGA TCA TGG CTC A-3′) and 1492R (5′-TAC GGT TAC CTT GTT ACG ACT T-3′) (both 10 μM)

Distilled water

Bovine serum albumin (BSA) 2% [(Roth, catalog number: 3854.2); see as well (Embacher et al., 2021)]

1% agarose gel for gel electrophoresis system [e.g., agarose powder (Sigma, catalog number: A9539)]

Polyethylene glycol 6000 (PEG) 20% (Roth, catalog number: 0158.1)

80% EtOH (-20 °C)

Nuclease-free water

Tryptone soya agar (TSA) plates (see Recipes)

TSA soft agar (freshly prepared on harvesting day, store at ~50 °C until usage) (see Recipes)

Liquid Tryptone soya (TS) medium (see Recipes)

Malt extract agar (MEA) (see Recipes)

Modified Melin-Norkrans (MMN) (see Recipes)

Hutner’s Trace metals (see Recipes)

0.85% NaCl solution (see Recipes)

Sodium borate buffer (20× Stock solution, pH 8) (for agarose gel electrophoresis, see Recipes)

Recipes

Tryptone soya agar (TSA) plates

Casein peptone 1.5% (w/v), 15 g

Soy peptone 0.5% (w/v), 5 g

NaCl 0.5% (w/v), 5 g

Agar 1.8% (w/v), 18 g

dH2O, add up to 1 L

(pH = 7.3 ± 0.2)

Prepare TSA medium, autoclave (120 °C), let it cool down, pour into Petri dishes, and let cool to room temperature (RT). Store at 4 °C.

TSA soft agar

Casein peptone 1.5% (w/v), 15 g

Soy peptone 0.5% (w/v), 5 g

NaCl 0.5% (w/v), 5 g

Agar 0.7% (w/v), 7 g

dH2O, add up to 1 L

(pH = 7.3 ± 0.2)

Prepare TSA medium and autoclave (120 °C). Store at ~50 °C until usage for plate casting after Koch.

Liquid Tryptone soya TS medium

Casein peptone 1.5% (w/v), 15 g

Soy peptone 0.5% (w/v), 5 g

NaCl 0.5% (w/v), 5 g

dH2O, add up to 1 L

(pH = 7.3 ± 0.2)

Prepare TS liquid medium, autoclave (120 °C), and let it cool down. Store at 4 °C.

Malt extract agar (MEA)

Malt extract 3% (w/v), 30 g

Soy peptone 0.3% (w/v), 3 g

Agar 1.8% (w/v), 18 g

dH2O, add up to 1 L

(pH = 3.5 ± 0.2)

Prepare MEA medium, autoclave (120 °C), and cool it down to 50 °C. Pour into Petri dishes and let cool to RT. Store at 4 °C.

Modified Melin-Norkrans (MMN)[after Tauber et al. (2016)]

Glucose, 5 g

(NH4)2HPO4, 0.25 g

KH2PO4, 0.5 g

MgSO4·7H2O, 0.15 g

CaCl2·2H2O, 0.067 g

NaCl, 0.025 g

FeCl3 (1%), 1.2 mL

Thiamine-HCl (10%), 1 μL

Hutner’s trace metals (0.01×), 100 μL

Agar, 20 g

dH2O, add up to 1 L

(pH = 5.6)

Prepare FeCl3, Thiamine-HCl (10%), and Hutner’s trace metals (0.01×) (Hutner et al., 1950) separately. Add them to the media while mixing on the rotary shaker. Measure the pH (and adjust if necessary) and adjust the media to 1,000 mL. Autoclave at 120 °C, let it cool down, pour into Petri dishes, and let cool to RT. Store at 4 °C.

Hutner’s trace metals

EDTA disodium salt, 50 g in 250 mL dH2O

ZnSO4·7H2O, 22 g in 100 mL

H3BO3, 11.4 g in 200 mL

MnCl2·4H2O, 5.06 g in 50 mL

CoCl2·6H2O, 1.61 g in 50 mL

CuSO4·5H2O, 1.57 g in 50 mL

(NH4)6Mo7O24·4H2O, 1.10 g in 50 mL

FeSO4·7H2O, 4.99 g in 50 mL

20% KOH solution (w/v)

For 1 L final mix, dissolve each component in the volume of water indicated. The EDTA should be dissolved in boiling water, and the FeSO4·7H2O should be prepared last to avoid oxidation.

Mix all solutions except EDTA. Bring to boil, then add the EDTA solution. The colour of the mixture turns to green. When everything is dissolved, let cool to 70 °C. While keeping the temperature at 70 °C, add 85 mL of hot KOH (20%). Cool to RT and fill up to 1 L final volume. Close the flask with a cotton plug (allows air exchange) and swirl it once a day while incubating for 1–2 weeks. Usually, the solution will initially be clear green but turns dark red or purple over the next few days, leaving a rust-brown precipitate. If no precipitate forms or the solution remains green, check the pH (should be at approximately 6.7; if there is a big deviation, try adding either KOH or HCl to adjust it).

Filter through two layers of Whatman #1 filter paper and repeat, if necessary, until the solution is clear. Store refrigerated or frozen in convenient aliquots.

0.85% NaCl Solution

Sodium chloride 0.85% (w/v), 8.5 g

dH2O, add up to 1 L

Prepare solution, autoclave (120 °C), and let cool down. Store at RT.

Sodium borate buffer (20× stock solution, pH = 8)

Boric acid, 48 g (concentration 1 M)

NaOH pellets, 8 g

dH2O, add up to 1 L

Prepare 900 mL of dH2O in a suitable container and add the boric acid and the sodium hydroxide to the solution. Stir until all solids are dissolved. Adjust pH to 8 by adding boric acid or NaOH. Fill to 1 L with dH2O.

Dilute the 20× stock solution to 1× before usage for gel electrophoresis (can be used for preparation for agarose gels and in the gel tank).

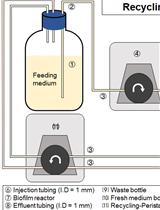

Equipment

Eppendorf centrifuge 5810 equipped with A-4-81 rotor (Eppendorf SE, Hamburg, Germany)

Heraeus FrescoTM 17 microcentrifuge equipped with 24 × 1.5/2.0 mL rotor with ClickSealTM biocontainment lid (Thermo Scientific, Waltham, Massachusetts, USA)

Counting chamber Thoma (depth: 0.01 mm, 0.0025 mm2, Assistent, Glaswarenfabrik Karl Hecht, Sondheim vor der Rhön, Germany)

Autoclave (HMC Europe, HICLAVE, catalog number: HGS-133)

Incubator (temperature range: 10–30 °C, e.g., Heraeus Vötsch, Vienna, Austria)

Benchtop orbital incubator shaker (New Brunswick Scientific, Edison, model: Innova® 40/40R)

Chemically resistant diaphragm vacuum pump model N810 FT.18 (KNF LABOPORT, Hamburg, Germany)

Vacuum filter manifold and sterile filtration funnels (Millipore SigmaTM, Microfil®, Merck Millipore Billerica, USA)

Nitrocellulose filter (0.45 μm; diam. 47 mm, part no: 1215230, GVS North America, Sanford, USA)

Overhead shaker model REAX2 (Heidolph Instruments, type: 541-21001-00)

Heating oven, 3.8 cu ft, 230 VAC (Memmert, UNB500/230 Basic Oven)

Balance (PM4600 DeltaRange®, Mettler-Toledo, Vienna, Austria)

Microbiological safety cabinet (Platinum SF, Kojair Tech Oy, Mänttä-Vilppula, Finland)

Carton package (to guarantee incubation in darkness)

Sterile glass Petri dishes (100 mm × 20 mm Rotilabo®, Carl Roth, Karlsruhe, Germany)

Sterile plier

Sterilizable punch (that gives e.g., plugs with ~0.8 cm × 0.7 cm × 1.1 cm)

Tweezers

PCR cycler (Primus 96 advanced, Peqlab Biotechnologie, Erlangen, Germany)

Horizontal gel electrophoresis system (RunOneTM Electrophoresis Cell, EmBi Tech, San Diego, USA)

Gel DocTM EZ Imager 30016395-0000 171800 (Bio-Rad Laboratories, Hercules, California, USA)

Thermomixer® comfort 5355 (Eppendorf SE, Hamburg, Germany)

Software

Microsoft Excel version 2209

RStudio version 4.0.3 (2020-10-10)

Procedure

文章信息

版权信息

© 2023 The Author(s); This is an open access article under the CC BY license (https://creativecommons.org/licenses/by/4.0/).

如何引用

Embacher, J., Zeilinger, S., Neuhauser, S. and Kirchmair, M. (2023). Co-culture Wood Block Decay Test with Bacteria and Wood Rotting Fungi to Analyse Synergism/Antagonism during Wood Degradation. Bio-protocol 13(19): e4837. DOI: 10.21769/BioProtoc.4837.

分类

环境生物学 > 真菌

微生物学

生物科学 > 微生物学 > 微生物群落 > 微生物组学

您对这篇实验方法有问题吗?

在此处发布您的问题,我们将邀请本文作者来回答。同时,我们会将您的问题发布到Bio-protocol Exchange,以便寻求社区成员的帮助。

Share

Bluesky

X

Copy link