- EN - English

- CN - 中文

Purification of Crimean Congo Hemorrhagic Fever Virus (CCHFV) Nucleocapsid Protein Using Detergent Gradient and Free Thawing

使用洗涤剂梯度和自由解冻纯化克里米亚刚果出血热病毒 (CCHFV) 核衣壳蛋白

发布: 2022年08月05日第12卷第15期 DOI: 10.21769/BioProtoc.4483 浏览次数: 1963

评审: Alessandro DidonnaNimesha TadepalleAnonymous reviewer(s)

相关实验方案

在杆状病毒表达系统中重组丙型肝炎病毒E2胞外结构域的表达和Ni-NTA-琼脂糖纯化

Julián Gómez-Gutiérrez [...] Belén Yélamos

2018年10月05日 6500 阅读

氨基甲酰转移酶测定: 5-羟甲基胞嘧啶 (5hmC) 到 5-氨基甲酰氧基甲基胞嘧啶 (5cmC) 的体外修饰

Weiwei Yang [...] Laurence Ettwiller

2022年09月05日 1982 阅读

Abstract

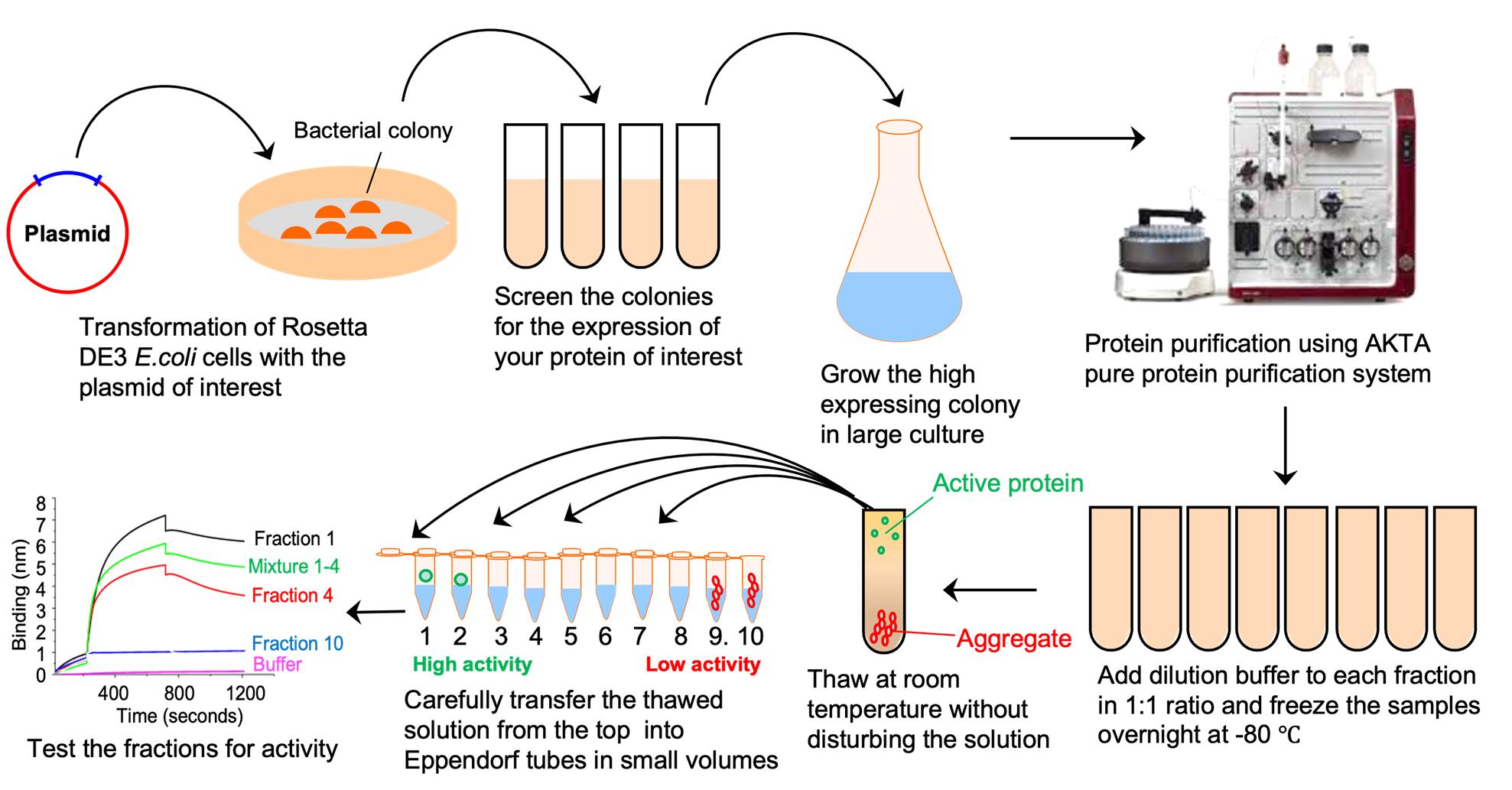

Protein aggregation remains a major challenge in the purification of recombinant proteins in both eukaryotic and prokaryotic expression systems. One such protein is the nucleocapsid protein of Crimean Congo Hemorrhagic fever virus (CCHFV), which has high aggregation tendency and rapidly precipitates upon purification by NiNTA chromatography. Using the detergent gradient purification approach reported here, the freshly purified protein by NiNTA chromatography was mixed with the dilution buffer containing a high detergent concentration, followed by overnight freezing at -80 °C. Thawing the resulting mixture at room temperature triggered the formation of a detergent concentration gradient containing the active protein in the low detergent concentration zone towards the top of the gradient. The inactive aggregates migrated to the high detergent concentration zone towards the bottom of the gradient. The method prevented further aggregation and retained the activity of the native protein despite numerous freeze–thaw cycles. This simple approach creates an appropriate microenvironment towards the top of the gradient for correctly folded proteins, and it prevents aggregation by rapidly separating the preformed early aggregates from the correctly folded protein in the mixture. This unique approach will be of potential importance for the biotechnological industry, as well as other fields of protein biochemistry that routinely purify recombinant proteins and face the challenges of protein aggregation.

Graphical abstract:

Background

Expression and purification of recombinant proteins from bacterial, viral, and eukaryotic expression systems is routinely carried out in the biotechnological industry, especially in the areas of development and commercialization of successful protein-based drug products. In addition, the expression and purification of recombinant proteins to study protein-protein, protein-nucleic acid, and protein-drug interactions, is routinely carried out in both academic institutions and the biotechnological industry. The inherent high aggregation tendency of proteins at various stages of expression, purification, and storage has significant impact upon product quality, safety, and efficacy. Unlike eukaryotes, the reduced environment of the bacterial cytosol and the lack of eukaryotic chaperones and post-translational machineries limit the efficient protein folding capability of a bacterial system. Due to these limitations, the huge expression of recombinant proteins in Escherichia coli (E. coli) often results in aggregation in inclusion bodies (Williams et al., 1982; Freedman and Wetzel, 1992; Chrunyk et al., 1993). The expression of the recombinant proteins at high translational rates exhausts the bacterial protein quality control system, resulting in the aggregation of partially folded and misfolded protein molecules to form inclusion bodies (Carrio and Villaverde, 2005). Formation of inclusion bodies poses a great challenge in the production and purification of recombinant proteins using E. coli as host. Purification of native-like proteins from inclusion bodies is extremely difficult. Despite the intensive processing, including the isolation of inclusion bodies from the cell, solubilization using denaturants, followed by refolding, the finally purified proteins tend to re-aggregate and show minimal activity. Protein aggregation in inclusion bodies can be reduced by decreasing the temperature of growing bacterial culture up to 16°C and reducing the inducer concentration. Although these efforts can be helpful for certain proteins, for most others the aggregation is triggered when bacterial cells are lysed during the purification process.

The detergent gradient approach discussed here for the purification of Crimean Congo Hemorrhagic fever virus (CCHFV) nucleocapsid protein (CCHFVNP) separates the early formed inactive protein aggregates from the correctly folded active protein and prevents further aggregation in the native protein sample. The correctly folded protein is retained in the appropriate microenvironment of the gradient, making the protein resistant to aggregation, despite numerous freeze–thaw cycles. The approach can be customized for the purification of any recombinant protein that is prone to aggregation. This native protein purification method produces a significant amount of pure protein without denaturation and refolding steps, commonly used in most protein purification procedures. The yield of the active protein produced by this method depends upon the aggregation tendency of the protein, which varies from protein to protein. If a protein has more aggregation tendency, the aggregates will move towards the bottom of the gradient, and little active protein stays on the top. For our protein (CCHFNP), almost 60% was aggregated, and the remaining 40% was active, which was pooled together and stored for later use. The approach will be of potential significance to the biotechnological industry, which faces challenges of protein aggregation at different stages of development and commercialization of protein-based drug products (Wang and Roberts, 2018).

Materials and Reagents

Toothpicks

Bacterial cultural tubes (MTC BIO, catalog number: T8235)

15 mL tubes (VWR, catalog number: 525-1070)

0.5 mL microtubes, black DNase RNase free (ARGOS, catalog number: T7456-001)

Plasmid pET-30a and Plasmid pET-CCHFNP

Triton X-100 (Fisher Bioreagents, catalog number: BP151-500)

HisTrap FF crude (Cytiva, catalog number: 17528601)

High Precision Streptavidin (SAX) (ForteBio, catalog number: 18-0037)

Rosetta (DE3) Competent Cells (Millipore Sigma, catalog number: 70954)

Kanamycin sulfate (Fisher Scientific, catalog number: BP906-5)

IPTG (IBI Scientific, catalog number: IB02125)

Protein ladder (Fisher Scientific, catalog number: 26616)

HisTrap FF crude (Cytiva, catalog number: 17528601)

Fraction collector F9-R (GE Healthcare, catalog number: 29011362)

T7 RNA polymerase kit (Promega, catalog number: P1300)

Biotin-11-CTP (Perkin Elmer, catalog number: NEL542001EA)

Bradford Protein Assay Kit 4 (Bio Rad, catalog number: 5000204)

1,000× Kanamycin stock (see Recipes)

1,000× IPTG stock (see Recipes)

Lysis buffer (see Recipes)

Elution buffer (see Recipes)

LB Broth (see Recipes)

LB Agar Plates (see Recipes)

5× SDS Loading Dye (see Recipes)

SDS-PAGE (see Recipes)

Coomassie Blue Staining solution (see Recipes)

Coomassie Blue Destaining solution (see Recipes)

Biotinylated RNA (see Recipes)

Dilution buffer (see Recipes)

RNA Binding Buffer (see Recipes)

Equipment

Spectrophotometer (Jenway, model: 6705; absorbance wavelength range 190–1,100 nm)

BLITZ probe (Nemko, forteBIO, model: BLITZ)

HPLC AKTA Pure 25L (GE Healthcare, Cytiva, model: 29018224)

Isotemp Incubator (Fisher Scientific, catalog number: 11-690-637D)

Excella E24 Incubator Shaker Series (New Brunswick Scientific, model: M1352-0000)

Allegra X-14R Centrifuge (Beckman Coulter)

Sonicator-Sonic Dismembrator Model 100 (Fisher Scientific, model: XL2000-350)

Legend Micro 17 Centrifuge (Sorvall, Thermo Scientific)

SDS-PAGE gel running system (Bio-Rad)

Software

Unicorn 7 (Cytiva)

BlitzPro 1.2 (ForteBio)

Procedure

文章信息

版权信息

© 2022 The Authors; exclusive licensee Bio-protocol LLC.

如何引用

Royster, A. and Mir, S. (2022). Purification of Crimean Congo Hemorrhagic Fever Virus (CCHFV) Nucleocapsid Protein Using Detergent Gradient and Free Thawing. Bio-protocol 12(15): e4483. DOI: 10.21769/BioProtoc.4483.

分类

生物化学 > 蛋白质 > 分离和纯化

生物工程 > 生物医学工程

您对这篇实验方法有问题吗?

在此处发布您的问题,我们将邀请本文作者来回答。同时,我们会将您的问题发布到Bio-protocol Exchange,以便寻求社区成员的帮助。

Share

Bluesky

X

Copy link