- EN - English

- CN - 中文

Solid Phase PCR on 3D Microstructure ArrayChip for Pathogen Detection Application

用于病原体检测的三维显微组织列阵中固相PCR

(*contributed equally to this work) 发布: 2019年08月05日第9卷第15期 DOI: 10.21769/BioProtoc.3323 浏览次数: 6287

评审: Imre GáspárKirsten A. CoprenAnonymous reviewer(s)

Abstract

Advanced free angle photolithography (FAPL) is presented for making 3D supercritical angle fluorescence (SAF) microstructures and transfer them on to polymeric chips using injection molding technique for low-cost microfluidic devices embedded with optical sensing structures. A solid phase polymerase chain reaction (SP-PCR) is used as model technique, which allows rapid and sensitive detection of pathogen DNA on-chip. This article presents the detailed fabrication of SAF structure and SP-PCR application on SAF structure for pathogen detection. This protocol of developing SAF structures using the FAPL process, increases the number of SAF per mm2. FAPL was performed via a motorized stage to control the angle of incidence and to achieve the desired bucket-shapes (dimensions of 50 μm to 150 μm with a slope) required for the 3D optical sensing. Due to the unique properties of SAF structures, it enhances the fluorescent signal by 46 times. Increasing the number of SAF structures and reducing the size resulted in reduction of sample volume required per test along with improvement in the limit of detection (LOD) due to a smaller size. This article also presents the experimental details of SP-PCR using DNA oligos bound to the SAF structures for on-chip pathogen detection and a comparison between different sizes of SAF structures. The direct on-chip SP-PCR paves the path for the application of this technique in point-of-care devices.

Keywords: 3D microstructures array (三维显微结构列阵)Background

The role of master mold is crucial to generate defect-free polymer chips in an injection molding process (Klank et al., 2002; Hong et al., 2010). This work presents a strategy to maximize on-chip 3D detection sites per mm2 with reduced defects and improved smoothness. Micro milling technique is conventionally used to make a rapid mold for injection molding. Due to the rough surface of milling bits it can cause defects in microstructures during molding. Significant efforts are being made towards improvement of molds by decreasing surface roughness and defects to achieve a better and smoother polymer chip (Ogilvie et al., 2010). Adding the novel FAPL (free angle photolithography) process we report here an improved fabrication of SAF structures and their transfer to the master mold and then to the polymeric chip.

The advantage of using SAF structures can be explained if we consider fluorophore molecule available on the front of a generic surface of microstructure: for a generic structure, most of the emitted light onto the material is refracted outside the structure, and only small amount of light passes through to give a signal (Ruckstuhl and Verdes, 2004; Winterflood et al., 2013). Usually, this refracted fluorescent light is lost or not been gathered when using a flat surface (microscopic polymer slide) for signal capturing. Collection of this remaining part of light by a structure that exhibits supercritical angle of reflection enhances the signal intensity up to 46 times (Hung et al., 2014). SAF structure offers a higher sensitivity and better view for efficient signal collection compared with the flat surface. Fabrication of SAF with photolithography improves the number of structures on a unit area of chip and reduces the volume of sample required. Incorporation of SAF structures on microfluidic chip in combination with SP-PCR provides the capability of multiplexed SP-PCR reactions on-chip for effective low-cost and compact optical detection platform. Our experimental results demonstrated that with SAF array it achieves ultra-sensitive limit of detection (LoD) for fluorophores. This sensitivity is comparable to that obtained by a conventional microarray with data acquisition from a high-end laser scanner. This SAF array platform is advantageous in terms of having a low cost microfluidic platform, whilst retaining high sensitivity and multiplexing capability.

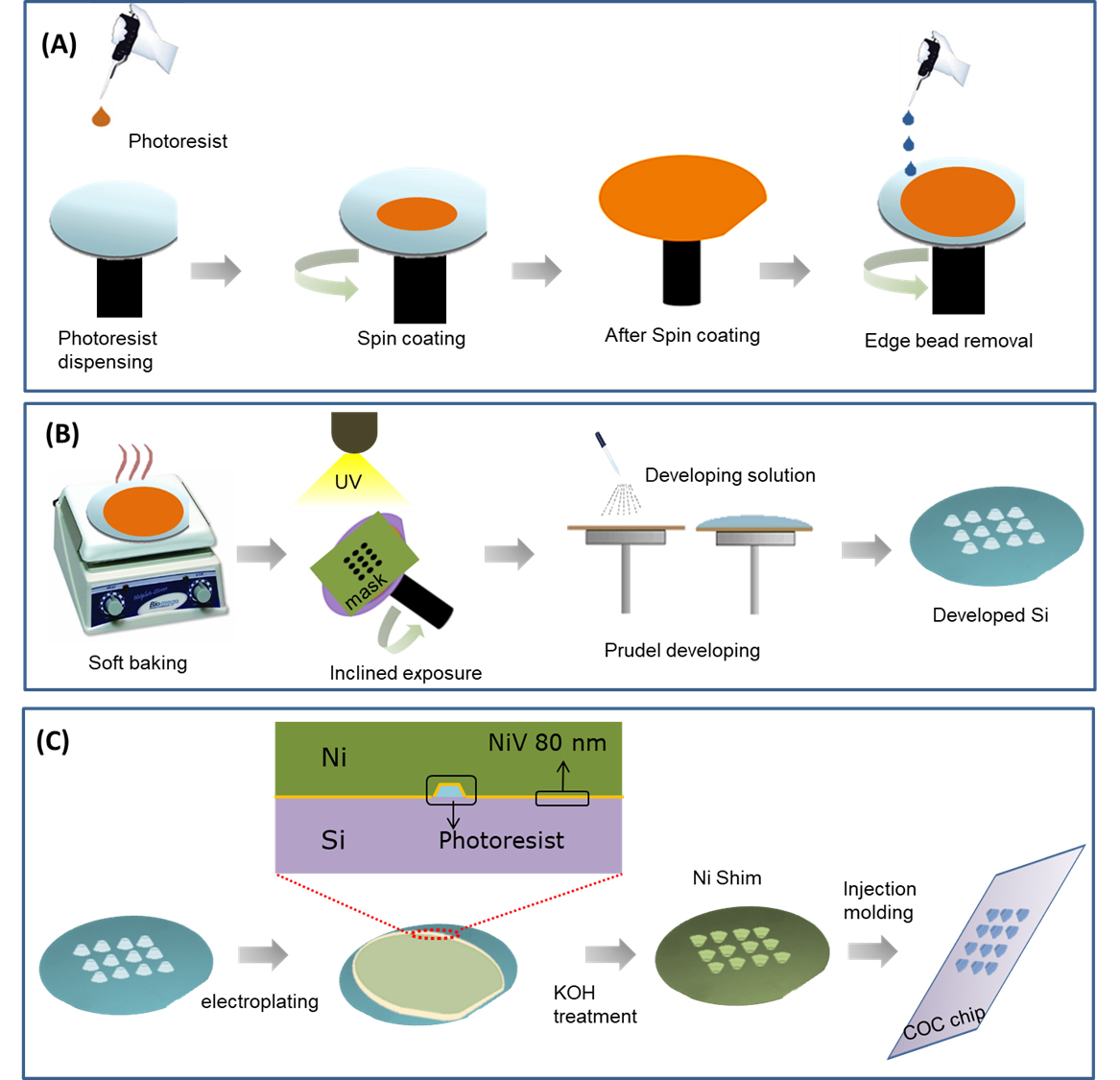

In this paper, we introduce FAPL fabrication process and demonstrate the possibility of achieving lithography-made SAF (L-SAF) structures with lower surface roughness and higher optical efficiency with respect to our previously described micro-milled SAF (M-SAF) (Hung et al., 2015). In particular, we present fabrication procedure (Figure 1) for L-SAF structures of different sizes (50 μm, 100 μm, 150 μm). Multiplexed SP-PCR reaction using DNA probes on L-SAF array for on-chip pathogen detection application (Sun et al., 2011) and our experimental outcomes confirmed that by using these improved SAF arrays, the limit of detection (LOD) could be improved up to 0.05 nM around 6.62 x 103 molecules. The LOD is calculated by data obtained from a high-end fluorescent scanner.

Figure 1. Schematic representation of fabrication steps of L-SAF array using FAPL process. Spin coating of photoresist and an edge bead removal is presented in (A), a free angle UV exposure over the rotatory chuck and development of the exposed Si is presented in (B), the transfer of fabricated 3D L-SAF array to polymeric chip using electroplating of the seed layer of NiV (80 nm) and thick layer (350 μm) of Nickel (Ni) for making a shim for injection molding is presented in (C).

Materials and Reagents

- Glass tip for spotting equipment (PDC 70 Piezo Dispense Capillary, Scienion, Germany)

- Microscope slide (75 mm x 25 mm x 1 mm) (VWR, Denmark, catalog number: 48311-703)

- Microscope slide cover, Gene frame (Thermo Fisher Scientific, Denmark, catalog number: AB0576)

- Negative tone photoresist THB 151N (JSR Micro NV, Belgium), store at cool (4-20 °C) and dark place

- Silicon (Si) wafer (Sigma-Aldrich, Denmark, catalog number: 646687-1EA, CAS Number: 7440-21-3)

- AZ726 MIF developer (MicroChemicals, Germany). Store at cool (4-20 °C) and dark place

- Acetone (Sigma-Aldrich, Denmark)

- TOPAS 5013L COC pellets (Advanced Polymers, Germany), store at room temperature

- DNeasy Blood and Tissue kit (Qiagen, Germany), store at room temperature

- Milli-Q water (Sigma-Aldrich, Denmark), store at 2-8 °C

- Bovine Serum Albumin (Sigma-Aldrich, Denmark), store at 2-8 °C

- Phusion Human Specimen Direct PCR Kit (Thermo Fisher Scientific, Denmark, catalog number: F150BID), store at -20 °C

- Saline Sodium Citrate Buffer, 20x concentrate (Sigma-Aldrich, Denmark, catalog number: SRE0068), store at 2-8 °C

- Triton X-100 (Sigma-Aldrich, Denmark, CAS Number: 9002-93-1), store at room temperature

- Tween-20 (Sigma-Aldrich, Denmark, CAS Number: 9005-64-5), store at room temperature

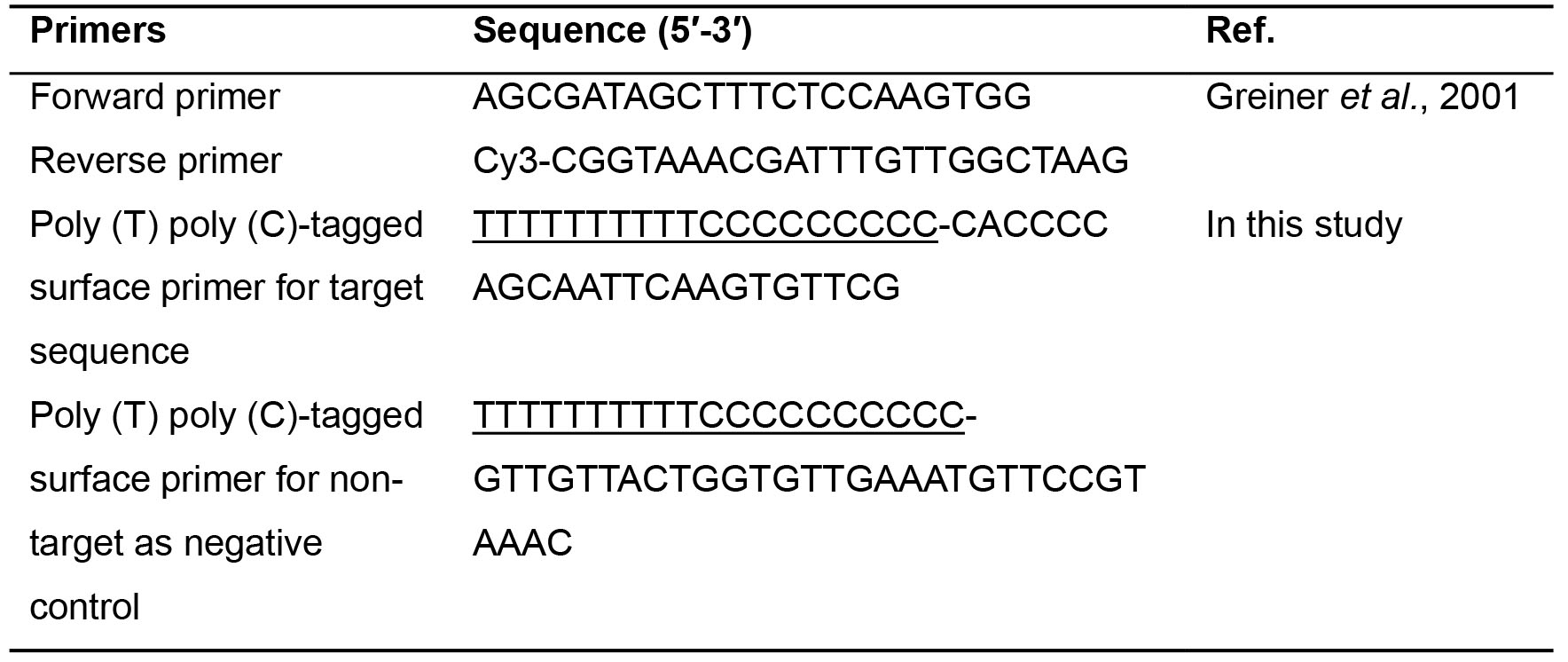

- Primers (Table 1): purchased from DNA Technology (Aarhus, Denmark)

Note: All primers are diluted in Milli-Q water (Sigma-Aldrich, Denmark) to a final concentration of 100 μM and stored at -20 °C.

Table 1. Primer sequences

Equipment

- Incubator (Thermo Fisher Scientific, catalog number: 50125590)

- Spin Coater (Karl Suss RCD8, Suss Microtec Germany)

- Hot plate (Thermo Fisher Scientific, catalog number: RC2235Q)

- AXXIS–Co-Sputtering (Kurt J Lesker, England)

- Nickel (Ni) electroplating (Microform.200, Technotrans)

- sciFLEXARRAYER S5 (Scienion, Germany)

- Injection molder (ENGEL Victory 80/45 Tech)

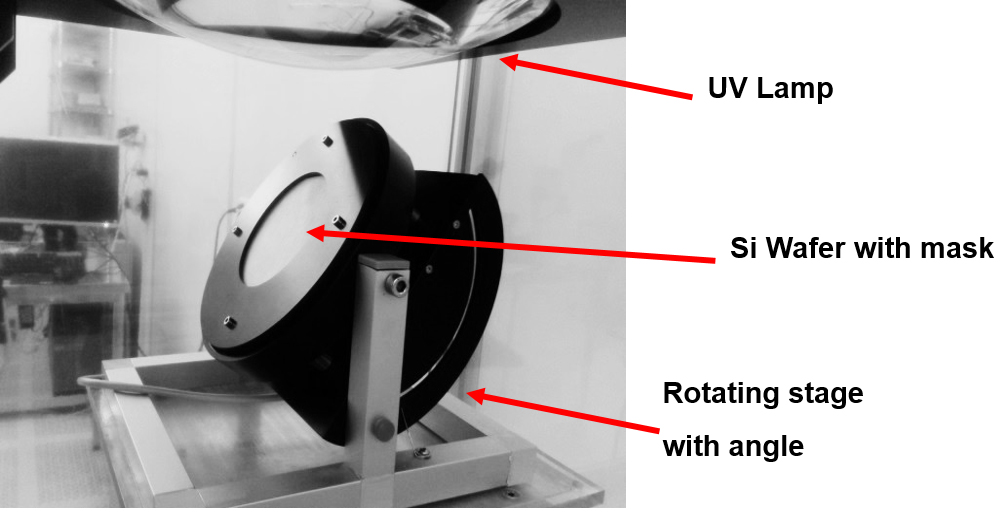

- Custom made rotatory stage for UV exposure (as presented below) (Figure 2)

Figure 2. A rotatory stage for free angle photolithography - Si wafers developing system after UV exposure (Gamma 2M Developer, Suss Micro-Tech, Germany)

- Surface profiler (Dektak XTA stylus profiler, Bruker, Denmark)

- BioAnalyzer 4F/4S scanner (LaVision Biotec GmbH, Bielefeld, Germany)

- Nanodrop 1000 (Thermo Scientific, USA)

- ProFlexTM 2x flat PCR System (Thermo Fisher Scientific, USA, catalog number: 4484078)

- Scanning electron microscopy (SEM) (FEI Quanta 200, USA)

Software

- Gwyddion 2.20 analysis software (http://gwyddion.net/download/2.20/)

- ImageJ software (https://imagej.nih.gov/ij/download.html)

Procedure

文章信息

版权信息

© 2019 The Authors; exclusive licensee Bio-protocol LLC.

如何引用

Kant, K. and Ngo, T. A. (2019). Solid Phase PCR on 3D Microstructure ArrayChip for Pathogen Detection Application. Bio-protocol 9(15): e3323. DOI: 10.21769/BioProtoc.3323.

分类

微生物学 > 病原体检测 > PCR

分子生物学 > DNA > PCR

您对这篇实验方法有问题吗?

在此处发布您的问题,我们将邀请本文作者来回答。同时,我们会将您的问题发布到Bio-protocol Exchange,以便寻求社区成员的帮助。

Share

Bluesky

X

Copy link